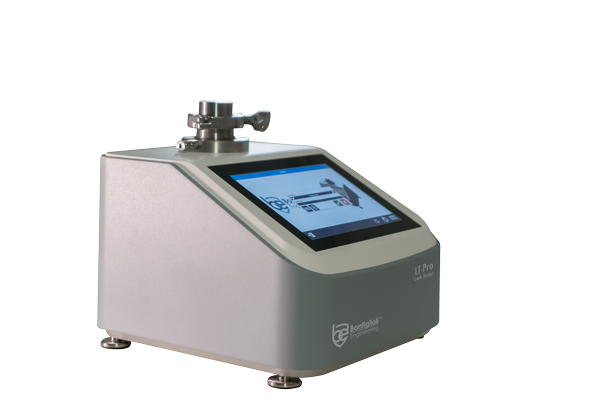

LT-Pro Leak Tester Flexible CCIT benchtop leak tester

Pharmaceuticals

Non-invasive, non-destructive leak tester for laboratory and in-process control applications. Provides accurate and reliable closed container integrity testing (CCIT) for rigid and flexible packaging.

PLAY VIDEO

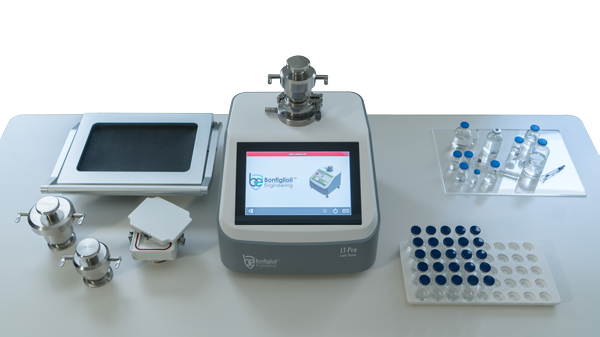

BFS

Bottles

Carpoules

Cartridges

FFS

Pouches

Prefilled Syringes

Vials

Flowpacks

Cups

Highlights

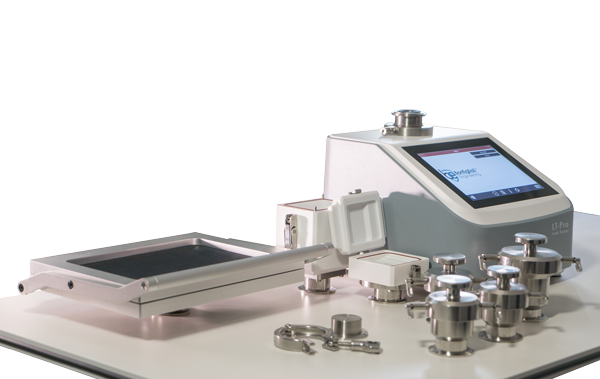

- Enhanced flexibility

- Interchangeable tooling for testing a wide variety of containers

- Multiple test methods: vacuum and pressure decay

- Available with either 5μm or 1μm test accuracy

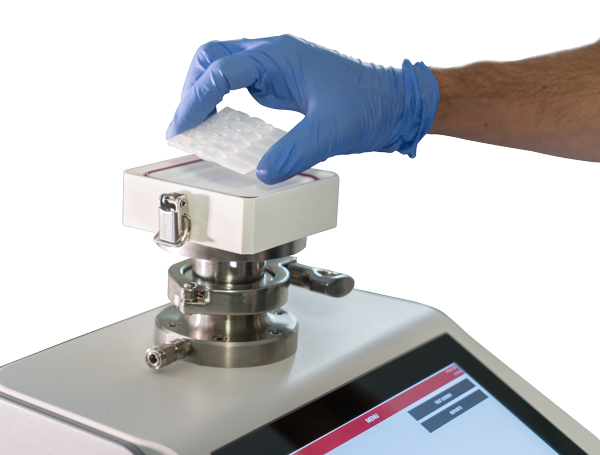

- Non-invasive, non-destructive testing of personalized medicine

- Small-batch testing

- Ergonomic design: lightweight, compact, easy to operate, clean, and move.

- Simple Ewon connection makes it easy to store, analyze, and document test results.